The Challenge of Precision in Laboratory Environments

Laboratories housing sensitive instruments demand precise stability to ensure accurate measurements. Any disruptions caused by external vibrations must be minimized. Instruments such as mass spectrometers, electron microscopes, and atomic force microscopes operate with extreme precision. They are highly susceptible to even the slightest mechanical disturbances. Stability is crucial.

Traditional stabilization methods, such as rigid mounts and damping systems, often fail to isolate low-frequency vibrations. These vibrations come from building movements, HVAC systems, and foot traffic. They distort experimental data. Research integrity depends on eliminating them. Solutions must be reliable, adaptable, and efficient.

Implementing Air Bellows for Vibration Isolation

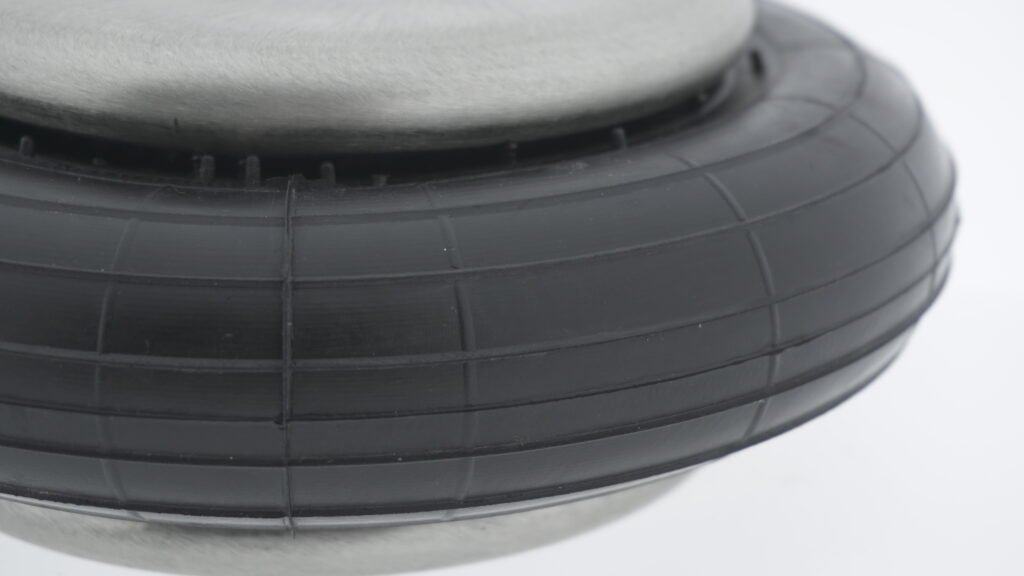

To combat these challenges, researchers opted for air bellows—a solution known for exceptional vibration isolation capabilities. Unlike conventional damping systems, air bellows operate on compressed air. They create a cushion that absorbs vibrations efficiently and reduces mechanical disturbances.

Key Advantages of Air Bellows:

- More than 99% vibration isolation

- Adjustable air pressure for customized stiffness and damping

- No stick-slip effect, ensuring smooth and precise movement

- Extended equipment life by reducing mechanical stress

- Low natural frequency, preventing resonance with common lab vibrations

- Wide range of operating pressures (4 to 12 bar depending on construction)

- Customizable materials (natural rubber, nitrile, EPDM, or chlorobutyl)

- Load capacities up to 450 kN per air bellow

The lab’s implementation of Tevema air bellows improved measurement accuracy. Vibration disturbances were reduced to negligible levels, ensuring more reliable research data.

How Air Bellows Enhance Instrument Stability

1. Low Natural Frequency

One of the primary reasons air bellows are preferred over conventional mounts is their low natural frequency. They are ideal for isolating low-frequency vibrations. Instruments requiring sub-micron precision need this level of stability. Even minor oscillations can lead to errors.

A triple-convolution air bellow can achieve a natural frequency as low as 1.4 Hz. This significantly reduces unwanted oscillations. The result is greater precision and stability in sensitive experiments.

2. Load Adaptability

Air bellows come in single, double, and triple convolution designs. This allows for customized solutions based on instrument weight and required isolation levels. Adjustable air pressure lets laboratories fine-tune the system for consistent performance.

For instance, a 12-inch, double convolution air bellow supports a dynamic load range of 40 kN to 100 kN. Adjustments ensure it meets the required stability specifications.

3. Compact and Maintenance-Free Design

Unlike mechanical springs and hydraulic dampers, air bellows require minimal maintenance. Their long service life makes them a cost-effective solution. Their compact height allows for seamless integration into laboratory setups without major modifications.

Additionally, stainless steel components (AISI-304 or AISI-316L) provide corrosion resistance. This makes them ideal for chemical-exposed environments where durability is essential.

Application in a Real-World Laboratory Setting

Case Study: Isolating an Atomic Force Microscope (AFM)

A research facility specializing in nano-scale imaging faced persistent vibration issues. These vibrations affected AFM performance, reducing accuracy. The solution was to install four Tevema air bellows beneath the AFM platform. This eliminated noise and improved scan resolution.

Results:

- Vibration levels reduced by 98.7%

- Increased measurement repeatability and accuracy

- Extended AFM lifespan due to lower mechanical stress

- Height control accuracy of ±0.1 mm due to adjustable air pressure

This case demonstrated the efficiency and reliability of air bellows in precision laboratory applications.

Selecting the Right Air Bellow for Laboratory Use

When choosing air bellows for instrument stabilization, key factors include:

- Load capacity: Ensure the bellows support the instrument’s weight

- Operating pressure: Match the required air pressure range (4 to 12 bar)

- Material compatibility: Choose materials resistant to chemicals and temperature fluctuations

- Mounting options: Determine whether a dismountable, crimped, or bead-ring design is best

- Stroke length and deflection: Ensure sufficient range for dynamic loads and movements

- Connection sizes: Verify that air inlet and mounting threads fit your system’s specifications

Selecting the right configuration ensures optimal vibration isolation and enhanced instrument longevity.

The use of air bellows in laboratory settings provides an effective and reliable solution for stabilizing sensitive instruments. They offer superior vibration isolation, adjustability, and long-term durability.

With low-frequency vibration isolation, high load capacity, and material customization, air bellows are a critical component in laboratories requiring stable, high-precision environments. Their adaptability and efficiency make them indispensable.