Air bellows, also known as air springs, are essential components in modern pneumatic systems due to their versatility and superior performance in both industrial and vehicular applications. Unlike traditional actuators and vibration isolators, air bellows offer features like maintenance-free operation, high load-bearing capacity, and excellent vibration damping properties. At Tevema, we design and produce various air bellows for diverse industrial uses, understanding the critical role these components play in ensuring the efficiency and longevity of pneumatic systems.

Versatile Uses of Air Bellows in Pneumatics

Air bellows find applications in numerous industries, from automotive to industrial machinery. Their ability to function as both actuators and isolators makes them ideal for a wide range of tasks, including precision lifting, vibration isolation, and shock absorption. This dual functionality offers significant advantages, particularly in industries requiring adaptable solutions for a variety of operational challenges.

1. Actuation in Pneumatic Systems

Air bellows are commonly used in pneumatic systems as actuators. Thanks to their frictionless movement and high thrust capacity, air bellows provide efficient force generation with minimal wear. Compared to traditional hydraulic cylinders or pneumatic cylinders, air bellows do not require lubrication or complex internal components, making them ideal for applications demanding reliability with little maintenance. They are particularly well-suited for use in environments where simplicity and durability are key factors in ensuring operational success.

For example, air bellows are used in scissor lifts and tilt tables, where precise control over movement is crucial. The lack of internal rods or seals reduces the risk of contamination, allowing air bellows to be used in environments with dust or dirt, ensuring consistent performance over time. The ability to operate without sliding seals makes air bellows particularly advantageous for outdoor applications or settings where maintenance opportunities are limited.

2. Vibration Isolation

Another significant application of air bellows is in vibration isolation. Air bellows produced by Tevema provide superior vibration damping by adjusting internal air pressure. This capability is vital for isolating sensitive equipment from external vibrations, particularly in industrial settings where machinery and tools are subject to frequent movement and external shocks. By isolating these vibrations, air bellows help prevent damage to precision equipment and enhance operational stability.

A typical scenario for vibration isolation using air bellows is in the protection of delicate machinery. By adjusting the air pressure to maintain an optimal natural frequency, air bellows can isolate up to 99% of unwanted vibrations, extending equipment life and improving safety. This kind of vibration control is particularly critical in sectors like pharmaceutical manufacturing and food processing, where maintaining precise operational conditions is crucial. The ability to adjust air pressure also allows for height control, ensuring stability and balance of supported equipment, which is essential for achieving a consistent output in production lines.

3. Load Support and Level Control

In addition to actuation and vibration isolation, air bellows are used extensively for load support and level control in pneumatic systems. Their inherent flexibility and adaptability make air bellows effective in supporting uneven loads, ensuring consistent height regardless of weight distribution. This capability to manage uneven loads helps prevent structural stress, ultimately reducing the likelihood of mechanical failures.

One example is the use of air bellows in platform lifts or vehicle suspension systems, where they automatically adjust the level to compensate for varying load conditions. The result is improved comfort, reduced stress on equipment, and enhanced control, which is especially important in applications like bus suspensions and heavy-duty trucks. With Tevema’s robust air bellows solutions, stability can be maintained even when loads are dynamic or shifting. Additionally, warehouse automation and logistics systems benefit significantly from air bellows, as they help maintain consistent alignment during loading and unloading, which leads to improved efficiency and safety.

4. Shock Absorption and Motion Control

Air bellows also excel as shock absorbers in pneumatic systems. Their ability to absorb sudden impacts makes them ideal for applications involving mechanical handling or vehicle axle suspensions. For instance, in a scissor lift, air bellows help with vertical motion and absorb shocks from rapid movement, safeguarding both machinery and operators. This shock-absorbing property is especially valuable in applications where equipment is exposed to frequent or unpredictable forces, such as construction equipment or mining machinery.

Similarly, air bellows are effective in controlling motion in vibratory conveyor systems and oscillating machinery. By utilizing air as the working medium, the bellows effectively mitigate back-and-forth motion, providing smoother operation and reducing wear on moving components. In packaging lines, for example, air bellows help to minimize product damage by maintaining a stable motion control, thereby reducing the risks of misalignment and ensuring product quality.

5. Enhanced Safety Features

In addition to their primary functions, air bellows also offer enhanced safety features. Due to their simple construction and lack of internal moving parts, they pose fewer risks of mechanical failure compared to traditional actuators. This simplicity contributes to a safer working environment, especially in hazardous industrial areas. When used as part of an integrated safety system, air bellows can help to prevent equipment overloading, as they automatically adjust their pressure to maintain safe operating conditions.

Air bellows can also be paired with auxiliary safety stops to prevent the actuator from exceeding its maximum height or collapsing beyond safe limits. This feature is critical in applications such as aerial work platforms, where operator safety depends on reliable height control. By providing consistent and reliable motion without complex maintenance needs, air bellows contribute to a safer and more dependable operation.

Advantages of Using Air Bellows

High Load-Bearing Capacity

Air bellows can bear loads ranging from a few hundred pounds to over 100,000 pounds, depending on the model and configuration. This wide load-bearing range is achieved thanks to reinforced rubber construction, featuring multiple plies of fabric reinforcement that enhance durability and resilience. This strength makes air bellows suitable for diverse applications, from supporting conveyor systems in manufacturing facilities to heavy-duty applications like railway suspension systems.

Maintenance-Free Operation

Unlike traditional actuators that rely on hydraulic or mechanical seals, air bellows are maintenance-free. The absence of sliding seals eliminates friction and reduces wear, resulting in a longer operational life without the need for constant lubrication or part replacements. This makes air bellows highly desirable for industries looking to minimize downtime and reduce overall maintenance costs, such as food processing or chemical plants, where frequent maintenance can lead to significant operational disruptions.

Adaptability and Customization

Tevema’s air bellows adapt to various operational environments. With options for single, double, or triple convoluted designs and different materials such as chlorobutyl or natural rubber, air bellows can be customized to meet specific requirements. This adaptability extends to their ability to operate with different working media, such as compressed air, nitrogen, oil, or water. Additionally, specialized coatings can be applied to the rubber bellows to enhance their resistance to chemicals or extreme temperatures, making them ideal for harsh environments like offshore drilling rigs or high-temperature manufacturing processes.

Materials and Construction

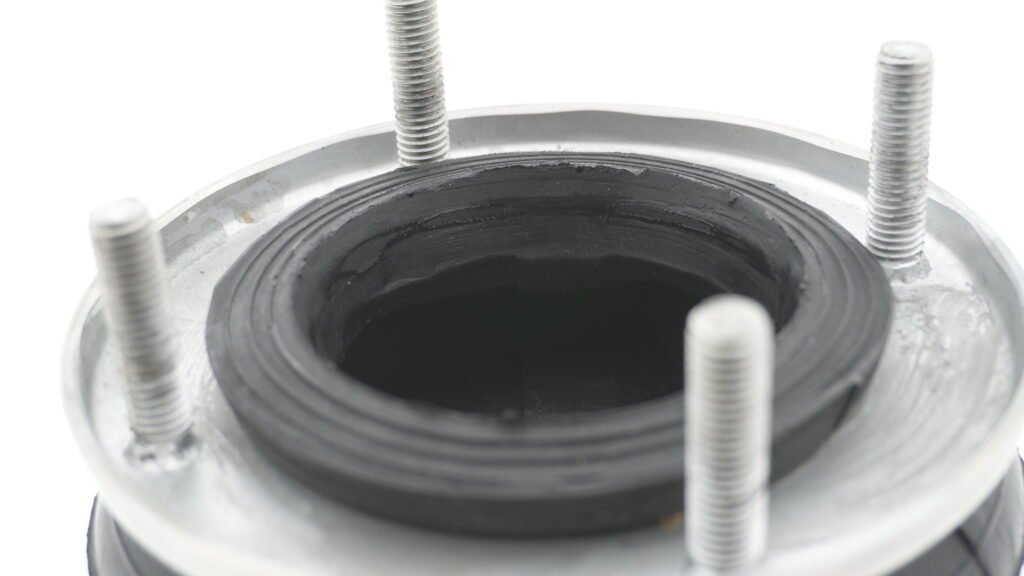

The construction of air bellows is critical to their performance in pneumatic systems. Tevema air bellows are made with high-quality rubber and reinforced fabric, designed to withstand harsh conditions, including extreme temperatures and corrosive environments. The end plates are typically made from galvanized steel or aluminum, providing durability while being resistant to rust and other forms of corrosion. These materials are selected not only for their strength but also for their ability to resist fatigue under constant load, ensuring a long lifespan for the air bellows.

The elastomer compounds used in air bellows are selected based on the specific needs of the application:

- Natural Rubber (NR/SBR): Standard material with excellent dynamic properties. Suitable for general applications with a temperature range of -40°C to +70°C. This material is preferred for its flexibility and durability in typical pneumatic applications.

- Chlorobutyl (CIIR): Offers outstanding resistance to acids, suitable for applications with a temperature range from -30°C to +115°C. Chlorobutyl is ideal for environments where chemical resistance is essential, such as wastewater treatment or chemical processing.

- Nitrile (NBR): Excellent for applications involving oils, fuels, or outdoor exposure, with a working range of -25°C to +110°C. Nitrile’s resistance to oils and fuels makes it well-suited for automotive and heavy equipment industries.

Air bellows play an indispensable role in pneumatic systems, offering advantages in actuation, vibration isolation, shock absorption, and load support. With their versatility, high load capacity, and maintenance-free operation, air bellows are a preferred solution for both industrial and automotive applications. At Tevema, we provide high-quality air bellows that cater to a wide range of needs, ensuring efficiency, reliability, and longevity in every application.

Whether you need air bellows for precision lifting, vibration isolation, or load support, our expert team at Tevema is ready to provide the right solution for your specific requirements. With our focus on quality and customization, we can help enhance the performance and safety of your pneumatic systems, no matter the industry.