Enhancing Bridge Stability with Air Bellows

In modern bridge construction, air bellows play a crucial role in reducing vibration and ensuring structural stability. Bridges endure constant stress from traffic loads, environmental conditions, and material fatigue, making vibration control essential for longevity and safety. Implementing air suspension technology significantly improves shock absorption, damping efficiency, and load distribution. The design pressure range for most air bellows varies between 6 and 12 bar, with a maximum load capacity of 450 kN. These components support thermal expansion, absorbing movement from temperature fluctuations. The use of high-strength elastomer materials ensures weather resistance and long service life. Tevema air bellows meet strict ISO 9001 quality standards, ensuring precision engineering and durability. Their compact installation height allows seamless integration into bridge support structures. Corrosion-resistant coatings further enhance longevity and reliability.

The Role of Air Bellows in Vibration Control

Bridges experience a variety of dynamic forces, including traffic-induced oscillations, seismic activities, and wind loads. Traditional metallic spring systems often fail to provide adequate flexibility and damping, leading to increased wear and tear. Air spring technology, however, offers superior shock mitigation, reducing the amplitude of vibrations through controlled air pressure regulation. By integrating air cushions, bridges maintain structural integrity while minimizing stress concentrations. The natural frequency of air bellows typically ranges from 1.2 Hz to 3.5 Hz, ensuring effective vibration isolation. Advanced models feature multi-layer reinforcement, providing enhanced mechanical stability under fluctuating loads. The use of four-ply reinforced bellows enables greater pressure resistance, making them ideal for high-traffic environments. Additional protective coatings prevent degradation from UV exposure, moisture, and chemical agents. These factors contribute to the superior vibration control performance of Tevema air bellows in bridge construction.

Advantages of Air Bellows Over Conventional Solutions

- Superior Damping Efficiency

Unlike coil springs, rubber-based air bellows effectively absorb high-frequency oscillations, preventing resonance amplification. Their low natural frequency allows better energy dissipation. - Adaptive Load Distribution

Through adjustable air pressure, pneumatic actuators accommodate variable loads, ensuring uniform force dispersion. This feature optimizes bridge balance and shock absorption. - Extended Service Life

The fatigue resistance of elastomer-based air springs prolongs bridge component durability, reducing maintenance costs. The high-wear-resistant materials enhance longevity. - Corrosion Resistance

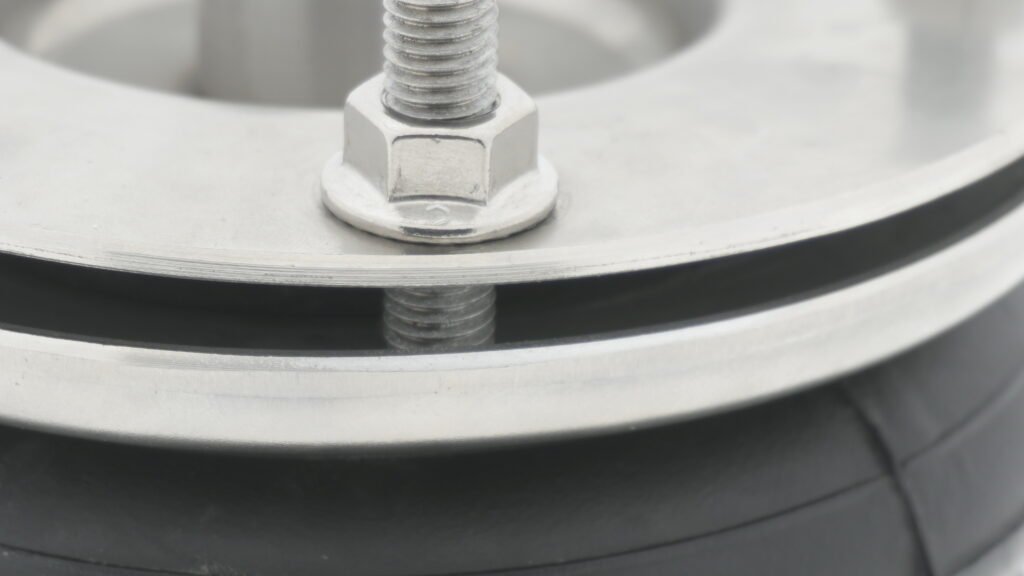

Unlike metallic suspensions, synthetic rubber composites in air bellows withstand humidity, salt exposure, and chemical erosion. Stainless AISI-304 and AISI-316 steel parts provide additional durability. - Compact Design & Lightweight Structure

The low-profile construction of air bellows enables space-saving installation, making them ideal for modern infrastructure applications. Their weight-saving advantage reduces structural stress.

Application of Air Bellows in Bridge Components

1. Expansion Joint Damping

Bridge expansion joints experience thermal expansion and contraction, causing structural misalignment. Air bellows-based isolators compensate for positional variations, ensuring continuous load support without inducing high-stress concentrations. These bellows operate within a stroke range of 50 mm to 375 mm, accommodating bridge expansion forces. The pressure-adjustable design allows precise load distribution. Their high-tensile reinforcement prevents failure under cyclic stress.

2. Shock Absorption in Support Bearings

Bridge support bearings endure oscillatory loads from moving vehicles and environmental forces. Incorporating air spring systems minimizes stress propagation, reducing fatigue damage in structural beams. The shock absorption capacity of air bellows varies between 8 kN to 300 kN, depending on the installed configuration. Their vulcanized elastomer structure ensures resistance to fatigue cracks.

3. Seismic Isolation Mechanisms

Bridges located in seismically active regions require high-performance shock isolators. Air bellows offer multi-directional damping, decoupling seismic tremors from bridge superstructures, thereby enhancing resilience against earthquakes. These bellows function with a maximum lateral displacement of 30 mm. Their reinforced bead plates provide secure anchoring, ensuring structural stability.

4. Load Balancing in Suspended Bridges

Suspension bridges rely on precise load distribution. Adjustable air bellows maintain dynamic equilibrium, preventing localized stress accumulation and mitigating torsional vibrations. The pressure-regulated design enables uniform force transmission across the bridge suspension system.

Why Choose Tevema Air Bellows for Bridge Engineering?

- Industry-Leading Durability

Tevema’s air bellows feature high-strength rubber compounds, ensuring long-lasting operational efficiency. Their reinforced internal layers provide increased fatigue resistance. - Optimized Vibration Isolation

Designed for civil engineering applications, Tevema’s air suspension units achieve over 99% vibration reduction. Their high-energy absorption rate enhances performance stability. - Custom Engineering Support

Tevema offers tailored solutions, assisting structural engineers in selecting the most suitable air bellow configurations. Custom diameter options range from 80 mm to 950 mm. - Proven Performance in Infrastructure Projects

With decades of experience in vibration control, Tevema’s air bellows have been integrated into numerous bridge installations worldwide. Their compliance with EN 45545-2 standards ensures fire-resistant properties.

Incorporating air bellows in bridge construction is a game-changer for structural longevity, load balancing, and vibration suppression. By utilizing advanced air suspension systems, engineers can enhance stability, safety, and maintenance efficiency in modern bridge infrastructure. Tevema’s precision-engineered air bellows provide the optimal solution for high-performance vibration isolation in civil engineering applications.