Maximizing Efficiency with Air Bellows in Vertical Lifting

Vertical lifting applications demand precision, reliability, and efficiency. Among the various lifting mechanisms available, air bellows stand out due to their versatility, high load-bearing capacity, and maintenance-free operation. Their compact design, adjustable stroke, and uniform force distribution make them indispensable for industrial automation, material handling, and heavy machinery. They allow for precise movement and controlled positioning, ensuring safety in high-load operations. The ability to withstand harsh environments makes them a reliable choice for long-term industrial use. With no need for lubrication or regular servicing, air bellows minimize downtime, increasing operational efficiency. Their adaptability in various applications makes them a crucial component in manufacturing and heavy-duty lifting.

Advantages of Air Bellows in Vertical Lifting

1. Superior Load-Bearing Capacity

Air bellows provide an exceptional lifting force that can handle loads from a few kilograms to several tons. Their ability to distribute pressure evenly across the surface ensures stable and controlled lifting, making them ideal for applications in automotive manufacturing, logistics, and robotic assembly lines. Load stability is critical in industrial operations, and air bellows ensure that weight is evenly managed. This prevents damage to machinery and ensures operational safety. The ability to accommodate heavy loads without compromising performance makes them suitable for high-stress environments. Unlike conventional lifting mechanisms, air bellows do not require complex support structures. Their self-sustaining design reduces dependency on additional reinforcements. With precise control over lifting force, operators can adjust performance based on application-specific needs.

2. Compact and Lightweight Design

Unlike hydraulic cylinders or mechanical lifting devices, air bellows require minimal space for installation. Their low-profile design allows for integration in compact environments, making them perfect for automated production lines and ergonomic lifting systems. Industrial settings often require space optimization, and air bellows enable compact machinery layouts. They can be installed in tight spaces without compromising performance. Their lightweight nature reduces overall machine weight, enhancing portability and efficiency. This is particularly useful in mobile lifting applications. Air bellows offer a flexible alternative to rigid lifting solutions. Their ability to adjust to various working conditions provides an added advantage. With fewer mechanical constraints, air bellows simplify system integration, reducing design complexity. Their adaptability ensures seamless performance in diverse operational setups.

3. Adjustable Stroke and Height Control

One of the standout features of air bellows is their precise height adjustment. The stroke length can be easily controlled by regulating air pressure, ensuring flexibility in operations such as height adjustment in conveyor systems and precision lifting in assembly lines. Height control is essential in industrial applications, and air bellows offer effortless adjustability. Operators can fine-tune lifting height for various tasks without requiring extensive modifications. The ability to achieve incremental height adjustments increases process efficiency. Unlike fixed-height lifting solutions, air bellows provide dynamic control. This makes them ideal for handling delicate materials requiring precise positioning. By adjusting air pressure, operators can optimize lifting performance for specific operational needs. This flexibility enhances adaptability across industries, from automated assembly to material handling.

Durability and Maintenance-Free Performance

4. No Sliding Parts = Reduced Wear

Air bellows operate without sliding seals or friction-based components, significantly reducing wear and tear. This ensures a long lifespan with minimal maintenance, lowering operational costs in industrial automation and vehicle suspension systems. Without mechanical friction, air bellows experience lower degradation over time. This makes them highly durable and cost-effective. Their simplified design eliminates the risk of lubrication-related failures. Traditional lifting solutions require ongoing maintenance to prevent mechanical wear. Air bellows eliminate this need, reducing downtime. They provide a more sustainable alternative to hydraulic and mechanical lifting systems. By minimizing wear, air bellows extend equipment lifespan. This enhances overall productivity and reduces replacement costs.

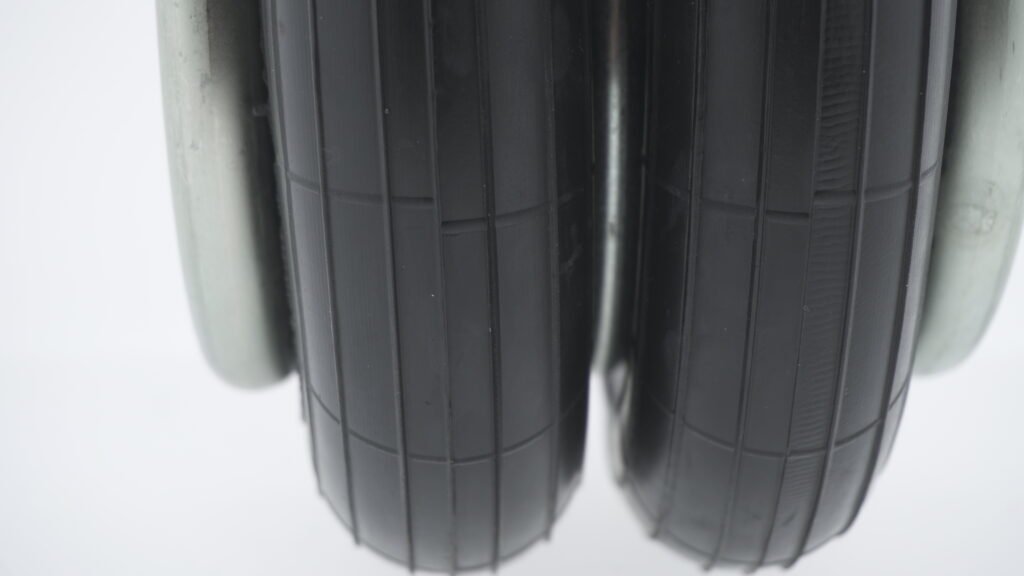

5. Resistance to Harsh Environments

Manufactured from reinforced elastomers and high-quality stainless steel, air bellows can withstand extreme temperatures, chemical exposure, and abrasive environments. This makes them ideal for offshore platforms, mining equipment, and food processing machinery. Corrosive environments pose challenges to conventional lifting systems. Air bellows are resistant to such conditions, ensuring reliable performance. Their material composition prevents degradation due to external factors. This makes them a preferred choice in industries requiring durability. Temperature resistance allows air bellows to function in extreme heat or cold. They maintain efficiency without compromising structural integrity. Their resilience against contaminants makes them suitable for hygienic environments. This is particularly beneficial in pharmaceutical and food production industries.

6. Vibration and Shock Absorption

One of the less obvious but highly valuable characteristics of air bellows is their ability to absorb vibrations and shocks. This makes them perfect for sensitive applications where reducing mechanical stress is crucial, such as in precision manufacturing equipment, rail transport systems, and aerospace testing platforms. Industrial machinery generates vibrations that can affect accuracy. Air bellows mitigate these effects by dampening shocks. This ensures smooth operation in high-precision applications. Vibration absorption reduces noise levels, improving workplace conditions. Sensitive components benefit from the stability provided by air bellows. They prevent structural damage caused by continuous mechanical stress. This enhances the longevity of critical equipment. Industries requiring precise motion control rely on air bellows for consistent performance. Their ability to absorb impact ensures smooth operation across various applications.

Air bellows are an ideal solution for vertical lifting applications due to their high load capacity, compact design, adjustable stroke, and maintenance-free operation. Their ability to operate in harsh environments, energy efficiency, and cost-effectiveness make them a preferred choice across multiple industries. Whether in industrial automation, ergonomic workstations, or heavy-duty lifting, air bellows provide precision, durability, and efficiency for seamless operations. Their ability to adjust height and absorb vibrations makes them superior to traditional lifting mechanisms. They enhance safety and ensure long-term performance. The reduced maintenance requirements contribute to long-term savings. Air bellows continue to be a versatile and efficient lifting solution for modern industries.