Vibration control is crucial in industrial applications, where precision, durability, and noise reduction play a vital role in operational efficiency. Air bellows’ vibration damping properties make them an ideal solution for heavy machinery, vehicle suspension systems, and industrial automation. With their unique ability to absorb shocks and reduce noise transmission, air bellows significantly enhance equipment longevity and workplace safety. These components effectively reduce mechanical stress on connected systems. They prevent excessive wear and tear on moving parts, which results in lower maintenance costs. The flexibility of air bellows allows for superior adaptability across various industries. Operators can fine-tune internal pressure to achieve optimal vibration isolation. Their ability to respond quickly to dynamic forces ensures consistent performance in demanding applications. This adaptability provides significant advantages over traditional vibration damping systems. By understanding the science behind air bellows, industries can maximize performance, efficiency, and safety.

How Air Bellows Absorb Vibrations

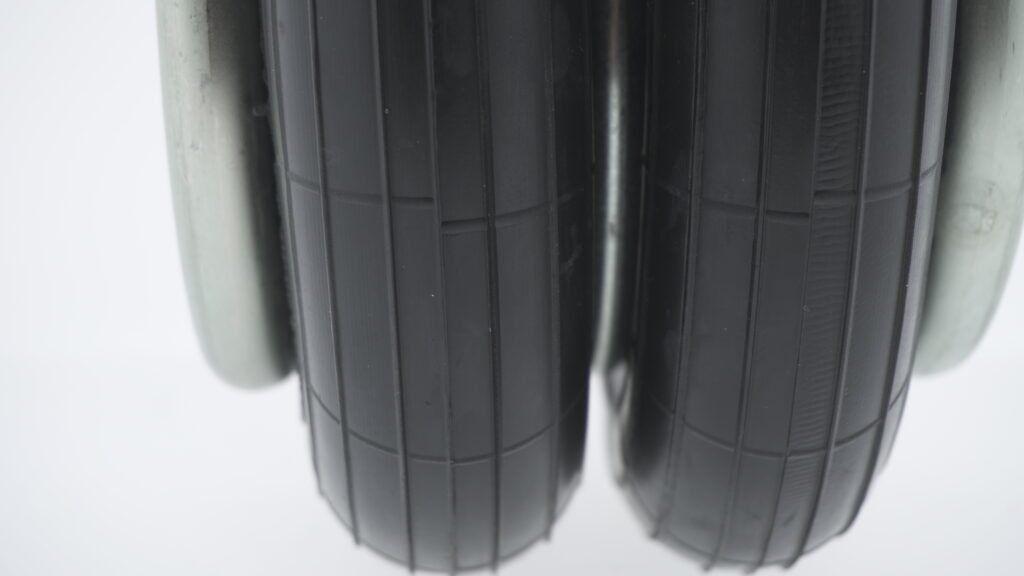

The core functionality of air bellows’ vibration damping lies in their low natural frequency and high load adaptability. These components operate by encapsulating compressed air within a reinforced rubber structure, which acts as a flexible yet robust barrier against external vibrations. Air bellows effectively mitigate high-frequency disturbances, preventing them from propagating through machinery. This results in less structural fatigue and increased longevity of industrial equipment. Air pressure regulation plays a key role in determining the stiffness and damping characteristics of these bellows. Operators can adjust internal pressure to match specific vibration isolation requirements. Materials such as natural rubber, nitrile, and chlorobutyl enhance durability and resistance to environmental factors. Structural design variations, including single, double, and triple convolution types, provide customized performance for different applications. Industries requiring precision damping solutions benefit from these adaptable and highly efficient air bellows systems.

Advantages of Air Bellows in Vibration Isolation

1. Extended Equipment Life

Air bellows reduce wear and tear on mechanical components by minimizing exposure to excessive vibrations. This lowers maintenance costs and enhances the durability of critical infrastructure. Excessive vibration exposure can weaken structural integrity, leading to premature equipment failure. Air bellows prevent this by absorbing energy and reducing stress on essential components. Their design ensures long-term reliability in challenging operating environments. Industries with high mechanical demands benefit from these extended life cycles. This leads to reduced downtime, allowing for uninterrupted production. Machinery subjected to intense vibrations benefits from longer operational lifespans with air bellows installed. Businesses investing in high-performance vibration damping see significant cost savings over time. The ability to sustain consistent load distribution further improves performance. Air bellows provide optimal shock absorption, allowing for controlled energy dissipation. This ensures extended operational longevity and better overall efficiency in industrial applications.

2. High Load Capacity with Compact Design

Unlike traditional coil springs, air bellows support substantial loads without compromising on installation height, making them ideal for space-constrained environments. The compact design allows for easy integration into existing industrial frameworks. Despite their small size, they can handle significant weight loads effectively. Air bellows distribute force uniformly, reducing pressure on machinery components. This prevents structural damage and enhances long-term durability. Their versatility makes them ideal for diverse industrial applications. Space-saving solutions are critical in modern industrial setups, and air bellows provide this advantage efficiently. Their ability to handle variable loads adds to their operational flexibility. Unlike metal springs, which can fail under high stress, air bellows maintain consistent damping efficiency. Compact designs make them ideal for vibration control in automated production systems. Air bellows are engineered for high-performance shock absorption, preventing excessive vibration transmission in sensitive equipment.

3. Adjustable Damping Characteristics

The ability to fine-tune air pressure ensures that air bellows provide optimal performance under varying loads and frequencies. Adjustability allows for customized vibration isolation tailored to specific applications. This flexibility makes them superior to rigid damping solutions. Traditional dampers lack dynamic adjustability, limiting their effectiveness in diverse operational conditions. Air bellows allow for precise tuning, ensuring maximum efficiency. The ability to modify stiffness in real-time enables better load adaptation. Operators can adjust internal pressure to accommodate changing operational demands. This ensures smooth performance optimization across different settings. Air bellows provide stable and consistent damping performance under extreme conditions. Their ability to compensate for uneven weight distribution further enhances their reliability. Adaptive damping solutions prevent resonance effects, reducing potential machinery damage. This flexibility ensures superior vibration isolation compared to conventional damping systems. As a result, air bellows remain a top choice for industrial vibration control.

Air bellows’ vibration damping capabilities provide an unmatched combination of performance, reliability, and adaptability. Their ability to absorb shocks, reduce noise, and enhance system longevity makes them indispensable across numerous industries. By selecting the right air bellows, businesses can achieve superior vibration control, improved efficiency, and extended equipment life. The science behind vibration damping highlights the critical role these components play in industrial applications. Operators seeking enhanced damping solutions benefit from integrating air bellows into their systems. Investing in advanced vibration control technology ensures maximum productivity and safety. As industrial demands evolve, air bellows continue to prove their effectiveness. Their adaptability across various applications solidifies their importance in modern engineering. Choosing the right air bellows guarantees long-term performance and operational efficiency. Understanding their unique damping properties enables businesses to make informed decisions regarding vibration isolation strategies.