In industrial and mechanical applications, selecting the right suspension or vibration isolation system is crucial. Air bellows and traditional metal springs offer unique solutions tailored to specific needs, but their differences can significantly impact performance and longevity. In this article, we explore these distinctions to help you make informed decisions when choosing the best solution for your requirements.

Materials and Construction

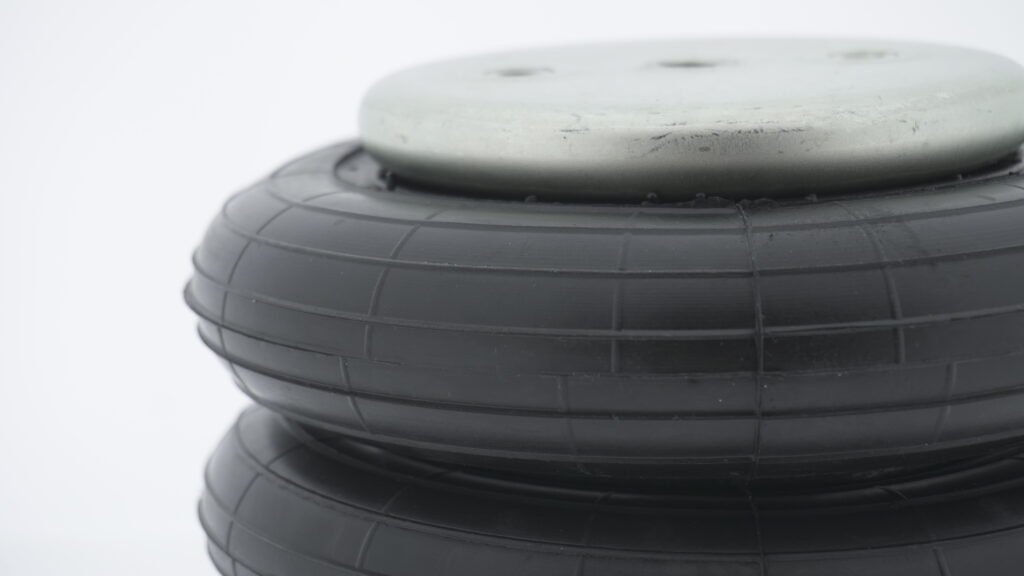

Air Bellows

Air bellows, also known as air springs, consist of a corrugated rubber body reinforced with fabric plies and fitted with metal end closures. These components are vulcanized together, resulting in a durable yet flexible product. The bellows can be made with materials like natural rubber, which offers excellent dynamic properties, or chlorobutyl, known for high resistance to acids. Other options include nitrile rubber, providing resistance to oils and ozone, and ethylene propylene diene, which excels in weather resistance. Additionally, metallic components are often made from galvanized steel or stainless steel to ensure durability under extreme conditions. Each material is carefully selected to meet specific industrial requirements, ensuring long-lasting performance and adaptability to challenging environments.

Traditional Metal Springs

Traditional metal springs are primarily composed of high-tensile steel. Depending on the application, they may include coil springs, which are helically wound steel wires, leaf springs, made of layers of flat steel plates, and torsion springs, designed to store and release angular energy. These springs are robust and widely used in static applications but lack the flexibility and material versatility of air bellows. While durable, their reliance on steel makes them more prone to fatigue and corrosion over time, often requiring additional maintenance to ensure optimal performance.

Functionality and Performance

Air Bellows

Air bellows offer unparalleled advantages in dynamic and static performance. Key features include adjustable stiffness, which allows for precise control by varying air pressure. Their low natural frequency ensures superior vibration isolation, with isolation levels often exceeding 99%. They can also tolerate lateral misalignments of up to 30 mm, making them ideal for applications requiring flexibility and adaptability. These attributes make air bellows suitable for vibration control, load leveling, and tilt motion capabilities of up to 25°. Their ability to perform under dynamic conditions enhances their appeal for advanced engineering systems.

Traditional Metal Springs

Metal springs are known for their simplicity and reliability in static applications. They offer high load capacity, making them ideal for supporting heavy, consistent loads. Their durability ensures long-lasting performance with minimal maintenance under controlled conditions. Additionally, they feature a compact design, efficiently storing energy in confined spaces. However, their inability to adapt dynamically limits their use in applications requiring variable performance. While effective for static systems, they lack the versatility of air bellows, making them less suitable for environments demanding frequent adjustments.

Applications

Air Bellows

Air bellows are commonly used in vehicle suspension systems, where they provide superior ride comfort by adapting to load changes. They are also integral to industrial machinery, offering vibration isolation and motion compensation. In actuator systems, they often replace hydraulic cylinders, delivering smoother operations with minimal maintenance. These versatile applications highlight their ability to enhance performance and reliability in demanding industrial settings. Their flexibility and vibration isolation capabilities make them indispensable in systems requiring adaptability and precision.

Traditional Metal Springs

Traditional springs find applications in mechanical assemblies, where they support static loads and absorb shocks. They are also widely used in heavy-duty trucks, providing reliable support in leaf spring suspensions. Additionally, they play a crucial role in precision instruments, delivering consistent force in confined mechanisms. While effective in these contexts, their design is more suited to static strength rather than adaptability, limiting their use in dynamic systems. This makes them a practical choice for simpler mechanical applications.

Cost and Maintenance

Air Bellows

Although the initial cost of air bellows may be higher, their low maintenance requirements and long service life often offset the expense. They can handle diverse media such as air, nitrogen, or even water, enhancing their cost-efficiency over time. Their resistance to wear and ability to adapt to varying conditions reduce the need for frequent replacements, contributing to lower operational costs. This long-term cost-effectiveness makes them an attractive option for industries prioritizing durability and flexibility.

Traditional Metal Springs

Metal springs are generally more affordable upfront. However, their susceptibility to corrosion and mechanical wear necessitates regular maintenance and eventual replacement, which can increase long-term costs. Their need for additional protective treatments and higher maintenance demands makes them less cost-effective over time, especially in environments requiring sustained performance. This factor often positions air bellows as a more viable solution for long-term applications.

Environmental Resistance

Air Bellows

Air bellows excel in challenging environments due to their weathering resistance and ability to remain unaffected by UV radiation or extreme temperatures ranging from -40°C to +115°C. Their material versatility also allows for chemical and oil resistance, making them suitable for industries where exposure to harsh conditions is inevitable. These qualities ensure consistent performance and reliability in demanding environments, further enhancing their value in industrial applications.

Traditional Metal Springs

Metal springs, while durable, are prone to corrosion, requiring coatings or treatments for protection. They also suffer from fatigue, where stress over time leads to cracks or failure in extreme conditions. Their performance is heavily influenced by environmental factors, often necessitating additional precautions to maintain their integrity and effectiveness. This vulnerability limits their utility in harsh conditions, making air bellows a more robust alternative for such environments.

Choosing between air bellows and traditional metal springs depends on your application requirements. Air bellows provide unparalleled versatility, adjustability, and vibration isolation, making them ideal for dynamic and high-performance needs. Conversely, traditional metal springs are reliable and cost-effective for static applications but may lack adaptability in changing conditions. By understanding the specific needs of your application, you can select the most suitable solution for optimal performance and longevity. For tailored solutions, our expertise ensures the right product for your needs.