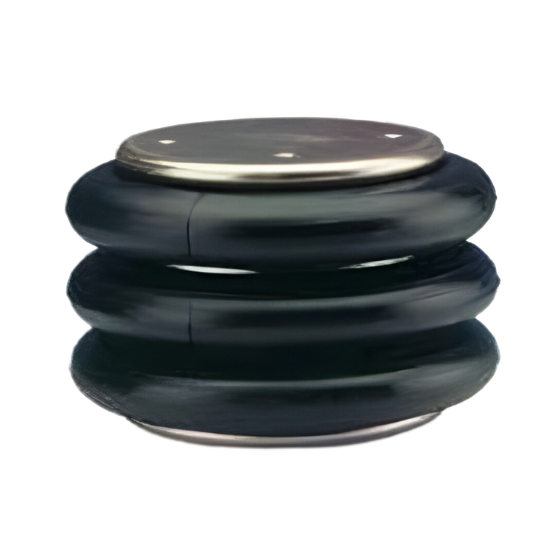

Maintenance-Free Operation

- Durability: With no moving parts, TEVEMA air springs require no lubrication or frequent maintenance, reducing operational downtime and costs. This maintenance-free design ensures long-term reliability and cost savings.

- Corrosion Resistance: Stainless steel options are available for environments exposed to acids and chemicals, ensuring longevity and reliability even in the harshest conditions.

Height Control and Uniform Isolation

- Height Regulation: Air pressure can be adjusted to maintain a consistent operating height, even with varying loads. This feature is crucial for applications requiring precise height control.

- Uniform Isolation Properties: TEVEMA air springs maintain constant natural frequency values despite changing loads, ensuring consistent performance.