Efficient supply chain management is critical for industrial air bellows. At our company, we understand complex tracking challenges clearly. Implementing blockchain technology can address these effectively. Each air bellow includes high-quality elastomers, reinforced fabric, and steel beads. Blockchain records provide immutable documentation of material specifications and quality checks. Decentralized blockchain ledgers increase transparency among all stakeholders. With clear and secure records, accountability significantly improves across supply stages. This transparency strengthens trust between suppliers, manufacturers, and clients. By adopting blockchain, we enhance supply reliability and efficiency. Real-time data sharing through blockchain reduces costly delays and miscommunications. Enhanced traceability ensures our components consistently meet rigorous standards. Blockchain is thus crucial for future-proofing operations and maintaining superior value.

Enhancing traceability with blockchain

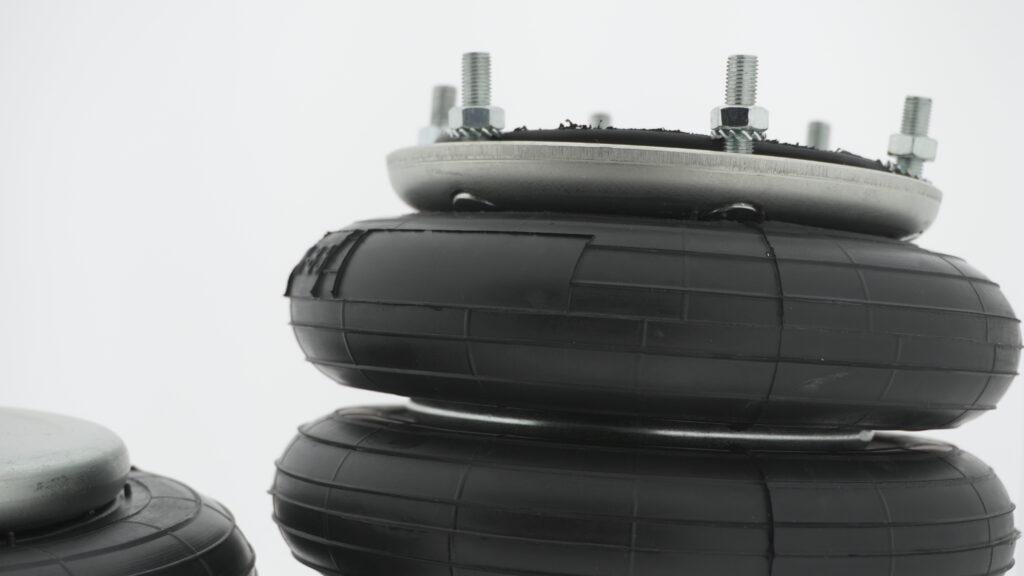

In manufacturing industrial air bellows, precise component tracking is essential. Blockchain assigns unique digital identifiers to each material and component. High-strength elastomer compounds like chlorobutyl and nitrile are recorded securely. Each stage of production from vulcanization to assembly has a transparent record. This immutable digital footprint immediately flags quality or compliance concerns. Real-time visibility through blockchain ensures swift corrective actions when necessary. Traditional systems suffer from delays and lack transparency. Blockchain offers accurate, immediate documentation for better response times. Precise traceability greatly reduces potential liability and improves customer confidence. Comprehensive records allow stakeholders instant access to verify product authenticity. Digital identifiers enhance accountability, ensuring rigorous adherence to industry standards. Blockchain’s permanent records significantly improve operational transparency and product safety assurance.

Reducing operational risks

Supply chains for air bellows involve multiple stakeholders with varying practices. Blockchain technology reduces operational risks through secure, transparent platforms. Cryptographic security ensures data integrity, preventing unauthorized access or alterations. Real-time data visibility significantly minimizes miscommunication risks across operations. Any data updates instantly reflect across the blockchain network. This transparency mitigates errors and inconsistencies common in traditional supply management. Blockchain technology eliminates data silos, facilitating seamless collaboration among suppliers and manufacturers. Enhanced communication increases trust, fostering efficient coordination between parties involved. With consistent data visibility, each stakeholder maintains accurate records securely. Decentralized blockchain ledgers strengthen supply chain resilience and predictability. Operational integrity improves substantially, enhancing overall security and management efficiency. Reduced risks lead to reliable and predictable production outcomes, increasing confidence in supply processes.

Streamlining inventory management

Managing inventory effectively for air bellows manufacturing is crucial. Blockchain technology provides real-time inventory updates accessible throughout the supply chain. Smart contracts within blockchain automatically manage reordering processes efficiently. When inventory reaches specific levels, smart contracts trigger automatic replenishment immediately. Proactive management prevents costly downtime, ensuring continuous production flow. Inventory levels remain optimal, minimizing excessive storage and associated costs. Accurate forecasting through blockchain enhances resource planning significantly. Each inventory movement is transparently logged, enabling precise stock management practices. Improved inventory accuracy reduces waste, optimizes storage space, and streamlines production timelines. Blockchain-driven inventory systems facilitate rapid responses to fluctuating demand scenarios. Enhanced precision leads to substantial cost savings, boosting customer satisfaction significantly. Streamlined inventory management through blockchain technology positions our operations competitively. Effective inventory control assures timely and efficient production schedules consistently.

Blockchain and quality assurance

Quality assurance is critical when producing high-performance air bellows. Blockchain technology provides transparent, permanent quality records for each production step. Detailed checks of elastomer compositions, such as natural rubber or EPDM, are documented securely. Every manufacturing milestone is immutably recorded, preventing unauthorized data modifications. Transparency in quality control swiftly identifies and addresses any production deviations. Immediate visibility significantly reduces waste and rework costs, improving profitability. Blockchain records ensure strict adherence to regulatory compliance and industry standards. Customers independently verify product quality and authenticity, fostering deeper trust. Continuous, secure documentation through blockchain enhances product reliability markedly. Blockchain technology ensures our air bellows maintain exceptional performance standards consistently. Comprehensive quality records provide unmatched product traceability and assurance. Blockchain significantly elevates reliability, durability, and customer trustworthiness in our products.

Improving supplier relations

Effective supplier relations are essential for industrial air bellows production efficiency. Blockchain technology enhances supplier interactions through transparent, real-time procurement data visibility. Suppliers clearly see inventory requirements, production schedules, and payment statuses instantly. Transparency reduces lead times by enabling proactive planning from suppliers. Blockchain-enabled smart contracts automate timely payments, avoiding disputes and delays. Improved efficiency and transparency significantly strengthen supplier trust and cooperation. Real-time data access allows suppliers to optimize resource allocation effectively. Enhanced coordination directly supports smooth production processes and timely material deliveries. Blockchain fosters long-term relationships through accountability and transparent collaboration. Strengthened supplier partnerships improve our capability to deliver consistent product quality. Blockchain-driven supplier relations optimize overall supply chain responsiveness and reliability. Embracing blockchain ensures our supply networks remain robust, efficient, and competitive long-term.