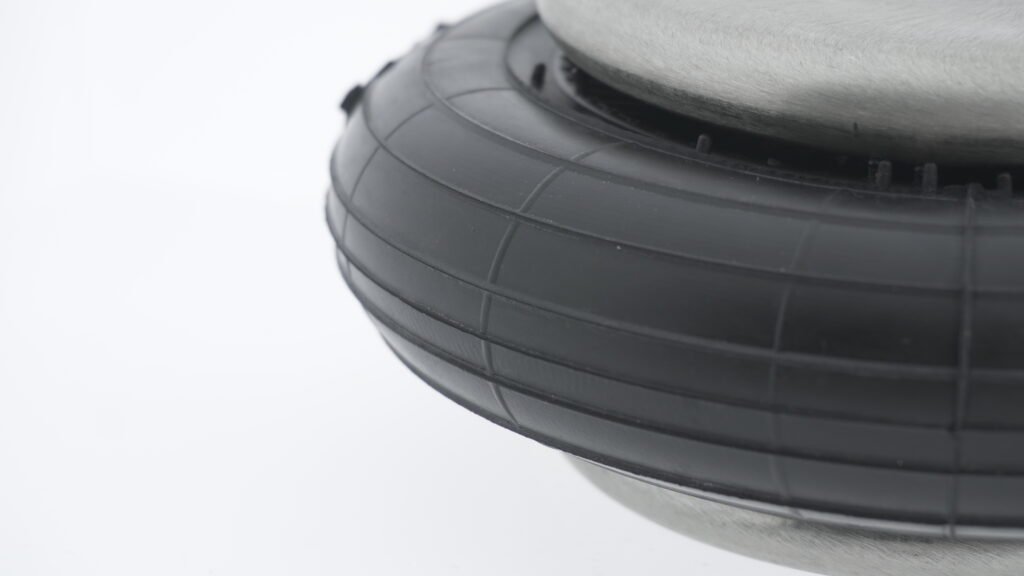

Medical devices require precise vibration isolation to ensure accurate diagnostics and patient safety. Air bellows play a crucial role in isolating unwanted vibrations from imaging machines, laboratory balances, and surgical tables. Unlike conventional dampers, air bellows offer adaptive stiffness, superior load-bearing capacity, and enhanced durability. They operate within a pressure range of 1 to 12 bar, supporting loads of up to 450 kN. Their stroke range varies from 20 mm to 400 mm, providing flexibility in applications. These features make air bellows a preferred choice for medical environments requiring stability and precision. Their maintenance-free design ensures longevity, reducing operational costs.

Why Air Bellows for Medical Equipment?

Air bellows provide 99% vibration isolation, which is essential for sensitive medical instruments. Their low natural frequency and adjustable air pressure enable customized vibration control. These benefits include:

- Reduced Noise Transmission – Prevents interference with diagnostic accuracy, ensuring consistent results.

- Extended Equipment Life – Protects machinery from excessive vibrations, reducing wear and tear.

- Height Control – Ensures consistent operating height under varying loads, maintaining stability.

- Compact Design – Ideal for constrained spaces in medical setups where precision is essential.

- High Load Capacity – Supports up to 450 kN, making them suitable for heavy-duty medical equipment such as MRI scanners.

- Customizable Pressure – Operates between 1 to 12 bar, allowing precise force adjustments for different applications.

Key Applications of Air Bellows in Healthcare

MRI and CT Scanners

MRI and CT scanners demand extreme precision to generate high-resolution images. Air bellows eliminate ground vibrations and electromagnetic interference, ensuring stable operation. Their effectiveness is based on low natural frequency, adjustable air pressure, and high load adaptability.

- Low-frequency isolation prevents distortion in imaging results, ensuring better diagnostics.

- Load adaptability enhances machine stability and minimizes external disturbances.

- Custom height control accommodates different patient positions, improving procedural accuracy.

- Electromagnetic shielding prevents imaging artifacts, ensuring high-quality scans.

Operating Tables

Surgeons rely on steady operating tables for precision. Air bellows eliminate floor-induced vibrations, ensuring stability during procedures. Their unique properties make them ideal for surgical environments.

- Dynamic response prevents unwanted movement, maintaining patient positioning.

- Adjustable pressure settings enhance ergonomic comfort, improving surgical precision.

- Silent operation maintains a disturbance-free environment, critical for operating rooms.

- Corrosion-resistant materials ensure durability in sterile conditions, increasing product lifespan.

Analytical Balances and Microscopes

Laboratory balances require micron-level precision. External vibrations can lead to measurement inaccuracies. Air bellows ensure precision in:

- Weighing pharmaceuticals with extreme accuracy, ensuring proper dosing and formulation.

- Microscopy imaging by reducing environmental disturbances that could blur images.

- Spectroscopy equipment where stability is critical for chemical and biological analysis.

- Temperature-resistant designs maintain consistent performance under laboratory conditions, preventing material degradation.

Engineering Features of Air Bellows

Material Composition

Medical-grade air bellows use:

- NR/SBR compounds for high elasticity and longevity.

- Chlorobutyl rubber for resistance to acids, cleaning agents, and hospital-grade disinfectants.

- Nitrile (NBR) rubber for oil and chemical resistance, making them suitable for laboratory environments.

- EPDM for extreme temperature resilience, ensuring stable performance in cold storage applications.

- Reinforced fabric layers for added structural integrity and extended product lifespan.

Pressure and Load Capacity

Standard air bellows operate at 8 bar, with high-strength variants reaching 12 bar. This high-pressure tolerance allows them to support medical equipment ranging from 50 kg to 450 kN. The maximum stroke range extends from 20 mm to 400 mm, providing greater flexibility in medical applications. These specifications ensure that air bellows can handle variable loads while maintaining consistent performance.

Mounting Configurations

Air bellows come in various mounting designs to suit different applications:

- Crimped end closures for compact applications where space constraints exist.

- Bead ring assemblies for high-load scenarios requiring secure attachment.

- Dismountable designs for easy maintenance and replacement in medical setups.

- Threaded fittings for quick installation and secure attachment to existing medical frameworks.

Comparative Analysis: Air Bellows vs. Conventional Isolators

| Feature | Air Bellows | Coil Springs | Hydraulic Dampers |

|---|---|---|---|

| Vibration Isolation | 99% efficiency | 60-70% | 85-90% |

| Load Capacity | High (up to 450 kN) | Moderate | High |

| Height Adjustability | Yes | No | Limited |

| Maintenance | Low | High | High |

| Noise Reduction | Yes (Silent Operation) | No | No |

| Stroke Range | 20 mm – 400 mm | Fixed | Limited |

| Pressure Adjustability | 1 – 12 bar | No | Yes |

Installation and Maintenance

Installation Guidelines

- Ensure correct alignment of the mounting plates to prevent structural imbalance.

- Adjust air pressure based on load requirements to optimize vibration isolation.

- Use stainless steel fittings for enhanced durability and resistance to corrosion.

- Inspect for proper sealing to prevent air leaks that could compromise efficiency.

Maintenance Best Practices

- Periodic pressure checks to maintain consistent performance across different medical devices.

- Inspect for air leaks and rubber wear to prevent equipment failures.

- Replace bead rings if signs of fatigue appear, ensuring longevity and reliability.

- Lubricate mounting points to prevent wear in high-frequency applications, extending service life.

In medical applications, air bellows provide an unmatched solution for vibration isolation, ensuring equipment longevity and operational efficiency. Their ability to deliver silent, precise, and maintenance-free performance makes them indispensable in healthcare settings. Investing in high-quality air bellows ensures optimal medical device functionality and improved patient outcomes. With their high-load capacity, adjustable pressure range, and corrosion-resistant materials, air bellows are the superior choice for medical vibration control solutions. Their ability to maintain stable, interference-free operation enhances the performance of critical medical imaging and analytical equipment.