Enhancing Industrial Stability with Advanced Air Bellows

Industrial plants require precise vibration control to ensure machinery efficiency, reduce wear, and improve safety. Air bellows provide a high-performance solution by offering superior vibration isolation, load adaptability, and extended durability. At Tevema, we specialize in engineering air bellows tailored for the rigorous demands of industrial environments. These components absorb mechanical vibrations effectively, preventing costly maintenance and downtime. Proper vibration control ensures that industrial equipment operates smoothly, reducing unnecessary stress on machinery and prolonging operational lifespan. With their flexible design, air bellows can accommodate various loads and movement requirements, making them ideal for diverse industrial applications. Their ability to function under extreme environmental conditions further enhances their effectiveness. By integrating these components into your machinery, vibration issues can be mitigated, leading to optimized performance and efficiency across all industrial operations.

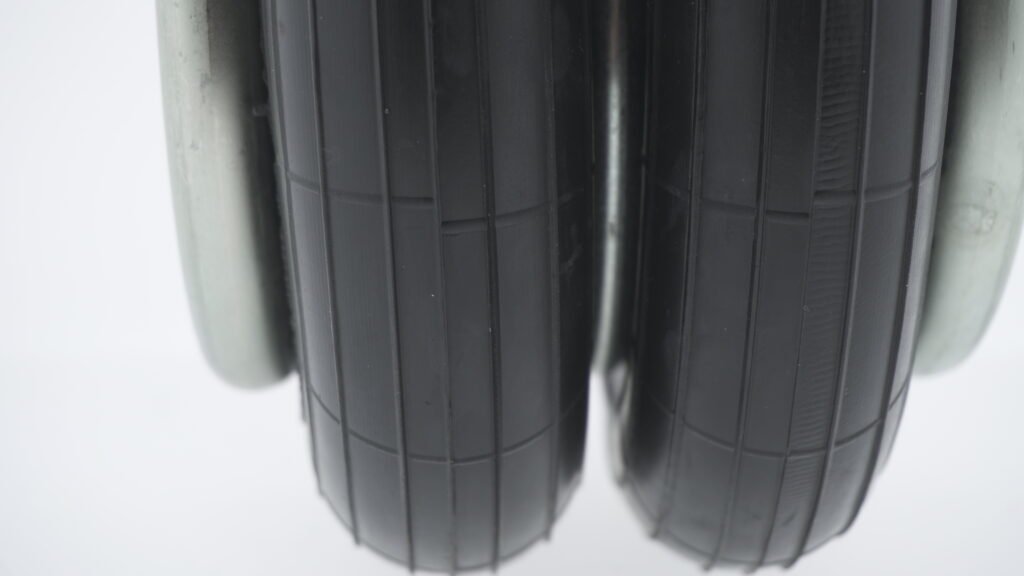

The Role of Air Bellows in Industrial Vibration Isolation

Damping Vibrations to Protect Equipment

Excessive vibration and oscillation in industrial machinery contribute to mechanical failures, misalignment, and unplanned downtime. Air bellows improve vibration isolation through:

- Variable air pressure control to adjust damping efficiency.

- Multi-layered elastomer composition for shock absorption.

- High-frequency response to ensure isolation from harmful vibrations.

Capable of absorbing over 99% of vibrations, air bellows extend the operational life of industrial equipment. They eliminate the transmission of unwanted oscillations, which can otherwise damage sensitive machinery. By adjusting air pressure, users can fine-tune their damping characteristics, achieving the best vibration control for their application. Effective vibration damping reduces stress on connected components, preventing premature wear and ensuring consistent machine performance. Air bellows also help mitigate the effects of external disturbances, maintaining the stability of the equipment. This feature is essential in environments with dynamic loads, where equipment must operate under constantly changing conditions.

Key Advantages of Air Bellows in Industrial Applications

- Precise Load Adaptability – Adjustable pressure compensates for load variations.

- Minimal Maintenance Requirements – No need for lubrication or mechanical adjustments.

- Compact Design – Ideal for space-constrained installations.

- Corrosion Resistance – Available in stainless steel configurations for harsh conditions.

- Customizable Solutions – Designed to fit specific operational needs, including size, shape, and pressure capacity.

Optimizing Air Bellows for Industrial Plants

Material Selection for Durability and Performance

Choosing the correct elastomer compound is crucial for long-term performance in industrial environments. Tevema offers multiple elastomer options:

- Natural Rubber (NR/SBR): Provides excellent dynamic flexibility, withstands temperatures from -40°C to +70°C.

- Chlorobutyl (CIIR): Offers high resistance to acids, operating between -30°C to +115°C.

- Nitrile (NBR): Ideal for oil resistance, with a temperature range -25°C to +110°C.

- EPDM: Excels in ozone and weather resistance, operating between -20°C to +115°C.

Each material is carefully selected to suit specific application requirements. Using the correct elastomer enhances resilience against environmental exposure, ensuring a longer service life. Factors such as oil resistance, temperature stability, and chemical exposure must be considered when selecting the best material. Industrial settings often expose components to abrasive elements, making material durability essential for long-term performance. Investing in the correct material prevents frequent replacements and reduces overall maintenance costs.

Construction Types and Their Benefits

Air bellows are available in three major configurations:

1. Dismountable Design

- Flexible assembly with bead rings and mounting plates.

- Ideal for adjustable applications.

2. Bead Ring Design

- Strong mechanical connection.

- Best suited for heavy industrial loads.

3. Crimped Design

- Permanently sealed structure.

- Enhances pressure resistance and long-term durability.

Each design has distinct advantages depending on the application. Selecting the correct configuration ensures that the bellows function optimally under specific conditions. Understanding the operational needs of an industrial plant helps in choosing the right type. Factors such as load capacity, pressure requirements, and environmental exposure should be evaluated when selecting a suitable air bellow design.

Technical Considerations in Air Bellow Design

1. Pressure and Load Calculations

Proper air bellow selection depends on pressure limits and load-bearing capacity. Tevema air bellows operate at:

- Standard pressure of 8 bar.

- Optional high-strength 4-ply construction for up to 12 bar pressure.

Calculating the appropriate pressure range ensures that the air bellows function efficiently without excessive stress. Overloading bellows beyond their designed pressure range may result in premature wear or failure. Engineers must carefully evaluate expected load variations to ensure optimal function. Load distribution across multiple bellows should also be assessed for uniform stability.

2. Height and Stroke Considerations

- Optimized stroke range prevents over-compression and excessive elongation.

- Height adjustments allow for stable operation across changing load conditions.

3. Installation Factors

- Ensure proper alignment to prevent uneven stress distribution.

- Use corrosion-resistant materials for extended durability.

- Account for lateral misalignment of up to 30 mm.

- Select proper mounting configurations to reduce stress on bellows components.

Tevema provides high-performance air bellows designed for industrial vibration isolation, machinery stabilization, and load adaptability. By selecting the correct material, construction type, and pressure settings, we ensure long-lasting and maintenance-free operation. Investing in quality air bellows enhances machinery reliability, reduces downtime, and increases efficiency in industrial plants. A well-engineered air bellow solution ensures consistent performance and protection against mechanical fatigue. Our expertise in engineering solutions guarantees that industrial plants receive customized, durable, and cost-effective solutions. Partnering with Tevema provides industrial businesses with a reliable vibration control system, ensuring maximum productivity.